Davey Textile Solutions Inc. is all about innovation. We want to continuously improve our products and processes to meet customer expectations while increasing efficiency and reducing waste. We also want to ensure the sustainability of our business and products now and for years to come.

OUR SUSTAINABILITY COMMITMENT

EXTENDED PRODUCER RESPONSIBILITY (EPR)

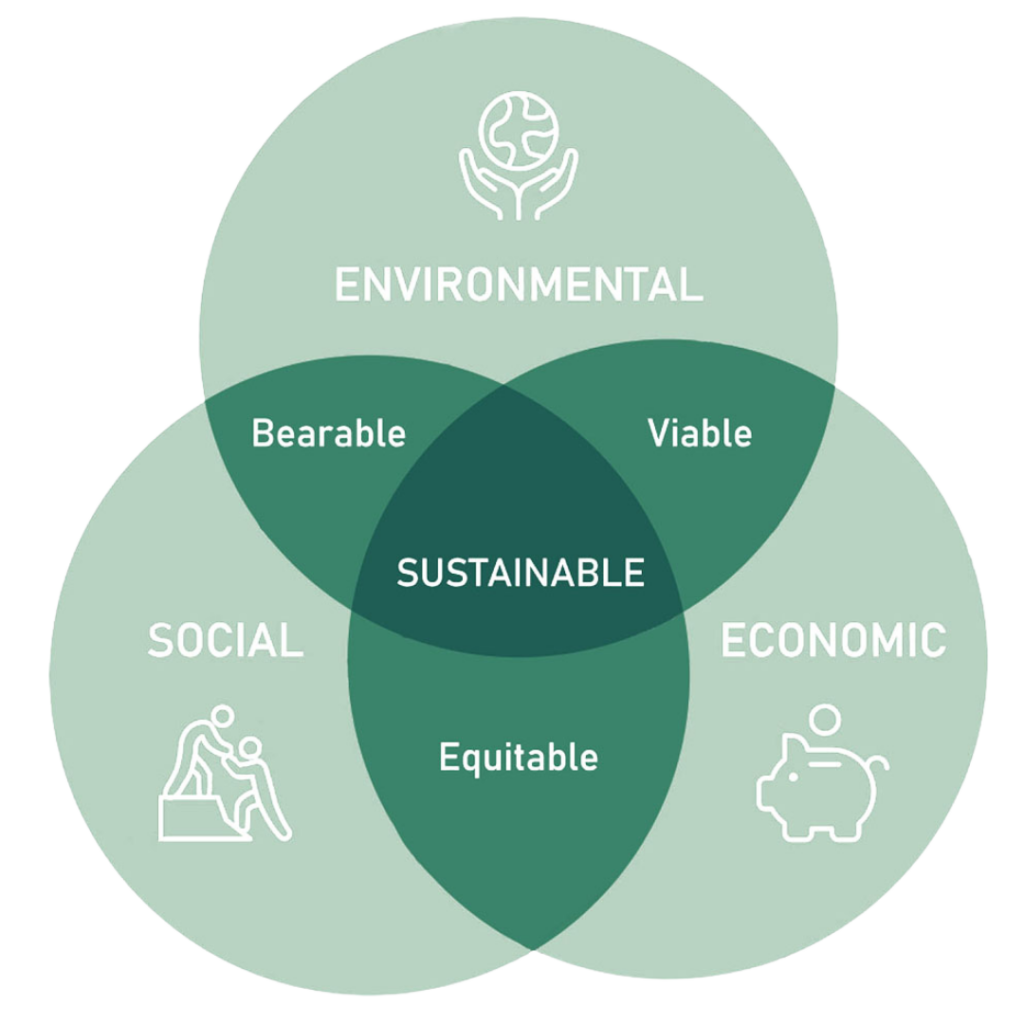

DTS aims to do our part to reduce or, better yet, eliminate any negative impacts our processes have on the environment and society. This practice is often referred to as extended producer responsibility (EPR) whereby manufacturers take financial and physical responsibility for the products they make until the end-of-life stage of that product. Consequently, we use a Triple Bottom Line approach when it comes to sustainability to ensure that business decisions and the products we make are bearable, equitable and viable and equally prioritizes people and planet alongside profit.

CIRCULARITY

We can attribute many of the environmental crises we are facing today to the traditional linear model of production, where we take resources and make products only to dispose of them as waste. Instead, we are working towards a circular model of production where products are designed for reuse, recycling or can degrade back into their natural components with energy for these processes coming from renewable sources.

SUSTAINABLE DEVELOPMENT GOALS

In 2015, the UN created the Sustainable Development Goals (SDGs), which are 17 categories of necessary action relating to social, environmental, economic sustainability. While this is a global strategy, individual companies can themselves contribute to the goals by implementing practices in alignment with the topics covered by the SDGs. At DTS, we look to the SDGs to determine what areas of action we can contribute to. We’ve identified Gender Equality; Industry, Innovation, and Infrastructure; Responsible Consumption and Production; Climate Action; and Life Below Water as direct goals we can contribute to with other goals being indirectly addressed through our various sustainability initiatives.

Sustainability Education

DTS believes that sustainability education helps our business and community make informed decisions regarding environmental impacts. We aim to provide information on basic sustainability concepts and initiatives to our employees, customers and the public through internal education initiatives and public social media posts. It is our hope that our educational efforts will create an impact within DTS and the greater community.

Safety Compliance

At DTS, safety is the core of our business. Our products are used for the safety of end users, ensuring they stay safe on the job site and make it home to their families. For this reason, we take the quality and performance of our products seriously.

We manufacture high visibility and flame-resistant materials that comply with Canadian and American safety standards including:

- Canadian Standards Association Group Z96 High Visibility Safety Apparel

- Canadian General Standards Board (CGSB) 155.22 Fireline Workwear for Wildland Firefighters

- American National Standards Institute (ANSI) 107 High Visibility Safety Apparel

- National Fire Protection Association (NFPA) 2112 Flash Fire Resistance

- We are continuously guided by our customers’ safety standard requirements. Currently, we are reviewing the International Organization for Standardization (ISO) and European Standard (EN) standards to determine the applicability to our customers’ needs.

Through involvement with the Standards Council of Canada (SCC), we maintain membership on many global standards committees including:

-

- CSA Z96

- CGSB 155.22

- American Association of Textile Chemists and Colorists (AATCC)

- International Organization for Standardization (ISO)

We consider involvement with these standards essential for ensuring that everchanging customer needs are reflected in the standards they are required to meet.

Environmental Sustainability

DTS strives to be a leader in sustainable manufacturing. Participating in the sustainability initiatives happening in the Canadian textile industry allows us to lead by example and advocate for SMEs within the industry.

Non-Hazardous Substances

We avoid the use of products and chemicals deemed hazardous by several global organizations including the Canada Hazardous Products Act, AAFA Restricted Substance list, US OSHA, U.S. Securities and Exchange Commission, EU REACH and EU RoHS. Furthermore, our production processes do not use per-and polyfluoroalkyl substances (PFAS) or perfluorooctane sulfonate (PFOS) substances. Our avoidance of hazardous substances protects human health and the environment.

Effluent

As of August 2020, we have been an active participant in an effluent toxicity study being conducted by Environment and Climate Change Canada (ECCC). The toxicity study aims to gauge the toxicity of our finishing process chemicals against aquatic organisms commonly found in our environment, with the goal of gaining an understanding of the environmental impacts of the Canadian textile industry. As the study is still in the testing phase, we do not currently have results to share. However, we are actively seeking more environmentally conscious process chemicals to reduce our impacts on aquatic environments.

Waste Reduction

Understanding our waste streams is essential for effective waste reduction and elimination. In the spring/summer of 2023, DTS began a comprehensive analysis of our production waste, focusing on department of origin and reason for disposal. With this analysis, we were able to create targeted reduction efforts tailored to each production department through quality control measures and process improvements. The targeted reduction efforts aim to prevent waste from occurring through close monitoring of equipment status and increased quality inspections. The results of our targeted efforts will be known upon further waste analysis to be completed in early 2024.

Waste Diversion

Although our goal is to prevent and reduce waste wherever and whenever possible, waste still occurs, making it our responsibility to divert waste to the best of our ability.

- We have a comprehensive recycling system with GFL Environmental Inc. and Waste Logic. Paper, cardboard, and plastics are recyclable through the GFL Environmental Inc. system. Recyclables placed in the Waste Logic bins are then diverted to the City of Edmonton system.

-

HDPE plastic dye tubes originating from our yarn suppliers are diverted to Alberta Recycled Plastic Lumber, where the tubes are shredded and compressed into plastic lumber for decking materials. As of March 2023, DTS has diverted over 107,000 dye tubes (approximately 10,400KG) from possible landfill to Alberta Recycled Plastic Lumber.

-

Reflective silver material off cuts and converted trim unable to be sold are diverted to Edmonton-based Reflective Advantage, a company making reflective garments for the safety of pedestrians and their pets.

Lyocell

Due to the environmental benefits and functional performance of lyocell fibres, we began investigating the opportunity to use Alberta-grown hemp as a source of cellulosic feedstock for lyocell. Hemp plants require less water and chemicals (i.e., fertilizers and pesticides) to grow and grows at a faster rate compared to conventional crops. Furthermore, hemp readily grows in the Albertan Environments. After conducting extensive background research, we are now in the experimental stage of manufacturing lyocell fibres from Alberta-grown hemp. Our Research and Development Specialist, Lelia Lawson, is currently pursuing her PhD at the University of Alberta to move us forward to the proof-of-concept stage. Once we have successfully expanded to a pilot scale, we plan to commercialize the business. This is a very exciting opportunity for us as lyocell fibres can be made flame-resistant through additives in the polymer stage, meaning that it has the potential to replace FR fibres in our production process that have higher environmental impacts.

You can read more about our lyocell initiative and Lelia’s research here.

Net Zero Commitment

In May 2023, DTS joined Environment and Climate Change Canada’s (ECCC) Net-Zero Challenge. The Net-Zero Challenge is a voluntary initiative that aims to encourage businesses to develop and implement credible and effective plans to transition their facilities to net-zero emissions by 2050. By committing to the challenge, DTS is joining a group of over 100 Canadian businesses committed to reducing their manufacturing and operating emissions.

As a member of the Net-Zero Challenge, DTS must meet several deadlines to ensure constant progress towards a net-zero future. Building on the work of the GIT carbon emissions report, we updated the baseline GHG inventory with 2022 energy usage data. Using the updated baseline data, we are creating realistic and achievable emissions goals for now and the future. Our first step in this journey is gaining an understanding of our energy use by equipment through an energy metering and management program. We look forward to keeping the community informed of our goals as we make progress towards net-zero manufacturing.

Energy Efficiency

Efficiency is a key component to our short-term and long-term net-zero and sustainability initiatives. By reducing demand, we are reducing the emissions from energy generation, reducing waste from entering the environment, and supporting financially sustainable manufacturing processes. Basic analysis of our production processes has allowed initial efficiency changes to be made. Efficiency changes include reducing waste through improved quality inspection, customer demand driven production, removing redundancies in production procedures and equipment upgrades. However, we are striving to implement greater impact efficiency targets. We are currently in the exploration phase of implementing energy management systems throughout our processes. Energy management systems will optimize our production processes resulting in the highest output for the lowest energy demands.

Long term emissions reduction plans has DTS exploring alternative energy sources and supplemental renewable energy for production and building processes. We explored common and unconventional alternative energy sources, including solar power, nuclear power, wind power, combined heat and power (CHP) and waste-to-energy systems. CHP and waste-to-energy systems proved the most viable of the options, and we will continue to explore these options into the future.

Canadian Green Textile Label

In 2024, the Canadian Textile Industry Association (CTIA) developed the Canadian Green Textile Label to be used by any company or organization that meets the following criteria:

- Commitment to Canada’s Net-Zero Challenge

- Submission of annual GHG emissions to CTIA

- Membership with CTIA