Our Sustainability Journey

We began our sustainability journey several years ago when Grant Davey, Jim Davey and Dan King succeeded Davey Fabrics from Al and Jan Davey in 2001 . In our transition from fabric supplier to manufacturer of high-visibility trim and retroreflective silver distributor, we worked closely with our main supplier, 3M, which has utilized the principles of Lean Six Sigma since 2001. Lean Six Sigma is a set of tools, strategies, and methods to continuously improve efficiency and eliminate wastes, while delivering quality and consistency to customers.

Through this collaboration with 3M, we implemented our first Six Sigma practice, 5S, as we navigated through the set up of our production facility. 5S refers to five steps – Sort, Set in Order, Shine, Standardize, and Sustain – to make spaces and processes more efficient, with less downtime and wasted resources. While not our intention at the time, Lean Six Sigma practices lent itself to environmental sustainability as resource use and waste was decreased. As noted by several institutions and academic literature, Lean Six Sigma is closely related to sustainability as these methods and practices help reduce waste, energy consumption and subsequent greenhouse gas emissions[1][2][3].

This introduction to Lean Six Sigma prompted our team to explore certification in lean manufacturing and processing. Many globally recognized institutions offer Lean Six Sigma training that begin with a Yellow Belt (classroom basics), and then progress through the Green Belt (Yellow Belt + project), Black Belt (Six Sigma Statistics + supervision of Green Belt projects) and Master Black Belt (training, coaching, and mentoring Green Belt projects) courses. As of September 2023, DTS has trained 14% of all staff in Yellow Belt, 21% in Green Belt and 7% in Black Belt. Assuming each of our Green Belt projects reduced our costs by about $50,000, we estimate that the implementation of lean manufacturing and processing has saved us over $500,000. In addition to financial savings, we have also seen significant reductions in material, labour, and time waste.

DTS has also investigated other sustainability initiatives throughout the years such as the feasibility of solar panels, filtering our wastewater, and combined heat and power energy generation; however, initiatives like these have never been formalized within our company. In 2022, we launched our Sustainability Team which began exploring how we can make Davey Textile Solutions a leader in sustainable textile innovation, in alignment with our company vision.

Why is Sustainability Important to DTS?

We use the definition of sustainability from the United Nations (UN) Brundtland Commission’s 1987 report which states that “sustainable development is development that meets the needs of the present without compromising the ability of future generations to meet their own needs”[4]. Current trajectories show that greenhouse gas emissions are not on track to limit global warming to the 1.5°C target[5], posing

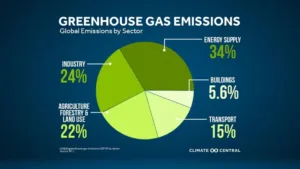

serious threats to all present and future forms of life on earth. According to 2019 figures from the Intergovernmental Panel on Climate Change (IPCC), the Industry Sector (which includes manufacturing) is responsible for 24% of total net anthropogenic GHG emissions4 (Figure 1).

Figure 1: Global emissions by sector (2019)[2].

We want to ensure we are doing our part to reduce or, better yet, eliminate any negative impacts our processes have on the environment and society. This practice is often referred to as product stewardship or extended producer responsibility whereby manufacturers take financial and physical responsibility for the products they make until the end-of-life stage of that product[4][5]. Accounting for the various potential impacts of our products necessitates a holistic perspective of sustainability, one that balances environmental, social, and economic aspects. Consequently, we use a three pillar Triple Bottom Line approach when it comes to sustainability (Figure 3).

Figure 2: Linear versus circular economy[3].

Figure 3: An overlapping model or Triple Bottom Line model of sustainability that equally prioritizes people and the planet alongside profit.

In 2015, the UN created the Sustainable Development Goals (SDGs), which are 17 categories of necessary action relating to social, environmental, economic sustainability[6] (Figure 4). While this is a global strategy, individual companies can themselves contribute to the goals by implementing practices in alignment with the topics covered by the SDGs. At DTS, we look to the SDGs to determine what areas of action we can contribute to. We’ve identified Gender Equality; Industry, Innovation, and Infrastructure; Responsible Consumption and Production; Climate Action; and Life Below Water as direct goals we can contribute to with other goals being indirectly addressed through our various sustainability initiatives.

How Do We Measure Our Sustainability Performance?

Historically, the success of a business has been defined by profit; however, we know profit is far from the only indicator of a company’s performance. Therefore, we use environmental, social and governance standards (ESG) as non-financial measures of performance[7] which mirror the three pillars of sustainability (Figure 5). Environmental standards relate to the impacts of practices on the environment, including carbon emissions, resource use, waste, and pollution. Environmental practices include energy efficiency, reducing water and chemical use, minimizing or eliminating waste, and reducing virgin or plastic-based material inputs. Social standards relate to the impacts of practices such as labour rights, equity, diversity, and inclusion (EDI) efforts, and community development on employees, stakeholders, and the broader community. Lastly, governance standards relate to the impacts of governance practices on the longevity of the business, including anti-corruption policies, data protection, board diversity, and financial transparency. According to UNEP, ESG standards “can be viewed as one of the methods and processes for achieving SDGs”12 (Figure 6).

Figure 4: The UN Sustainable Development Goals

Figure 5: Environmental, social, and governance pillars[8]

Figure 6: The SDGs categorized by ESG standards.

In Canada, there is no mandatory reporting required by businesses on their ESG practices. However, there are third party organizations that provide guidance on how a company can measure and report on key performance indicators (KPI) for environmental, social and governance sustainability. The main concern with any reporting on sustainability is greenwashing or providing misleading information about a company’s environmental practices. Therefore, we want to communicate our practices in a manner consistent with globally recognized reporting standards.

We are exploring and/or adhering to the reporting requirements outlined by:

Reporting according to these international standards enables credibility, consistency, and transparency on how we are positively or negatively contributing to sustainable development. The first step in this process is understanding our current impacts through a materiality assessment12. This involves identifying key issues relevant to the company, collecting data, prioritizing issues to address (based off severity and likelihood) in alignment with company vision and mission and then reporting on progress. Based on this assessment, we will determine areas of action to reduce our negative impacts and positive contribute to the SDGs. Lastly, in alignment with our Lean Six Sigma culture, we will continuously improve our processes to work towards greater environmental, social, and economic sustainability.

References

[1] What is a circular economy? | Ellen MacArthur Foundation

[2] Peak CO2 & Heat-trapping Emissions | Climate Central

[3] Ōhanga āmiomio – Circular economy | Ministry for the Environment

[4] Extended Producer Responsibility – OECD

[5] https://www.alberta.ca/regulated-extended-producer-responsibility-programs

[6] publications/Practical_Guide_SDG_Reporting.pdf

[7] building_a_sustainable_future_esg_business_handbook.pdf (undp.org)

[8] ESG reporting and preparation of a Sustainability Report | PwC Slovakia

[1] Seuring, S., and Müller, M. (2008). From a literature review to a conceptual framework for sustainable supply chain management. J. Clean. Prod. 16 (15), 1699–1710. doi:10.1016/j.jclepro.2008.04.020

[2] Environmental Professional’s Guide to Lean and Six Sigma: Chapter 1 | US EPA

[3] Ali, Y., Younus, A., Khan, A.U. and Pervez, H. (2021), “Impact of Lean, Six Sigma and environmental sustainability on the performance of SMEs”, International Journal of Productivity and Performance Management, Vol. 70 No. 8, pp. 2294-2318. https://doi.org/10.1108/IJPPM-11-2019-0528

[4] Our Common Future: Report of the World Commission on Environment and Development (un.org)