Challenges

Davey Textile was experiencing various data automation issues such as:

- Manual data collection, inaccurate detection and recording of downtime events

- Limited data availability, access, analysis visibility and collaboration

- Arbitrary targets in production capacity and equipment utilization

- Issues with decision making – they were relying on past experience and “gut feel” rather than data and information

- Capacity was a clear bottleneck

The Downtime Tracker was then developed into a long-term solution. Here were the four main goals:

- Identify barriers to success

- Quantify production losses incurred by downtime

- Identify variation in the production

- Highlight downtimes and notify personnel

Solutions

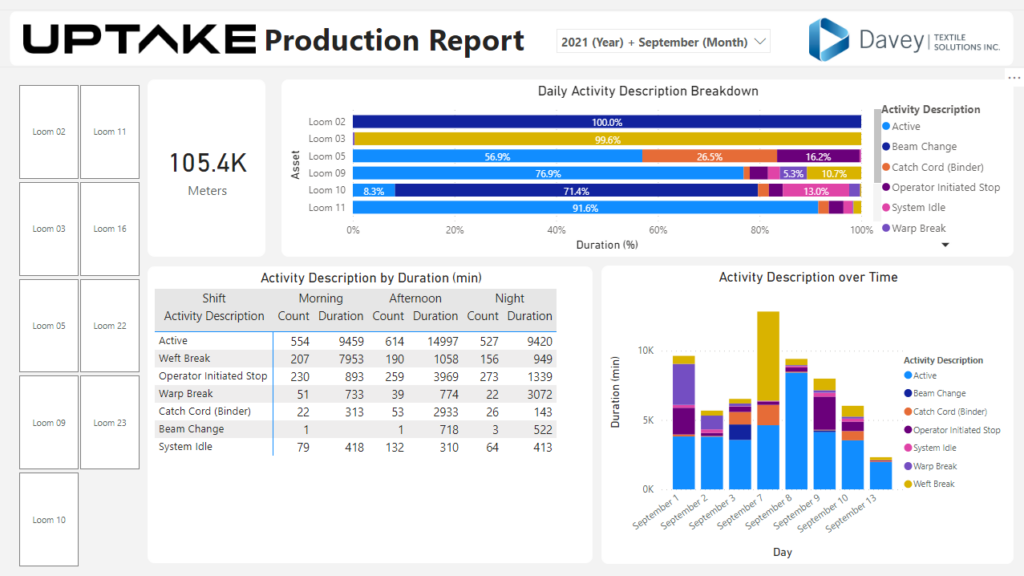

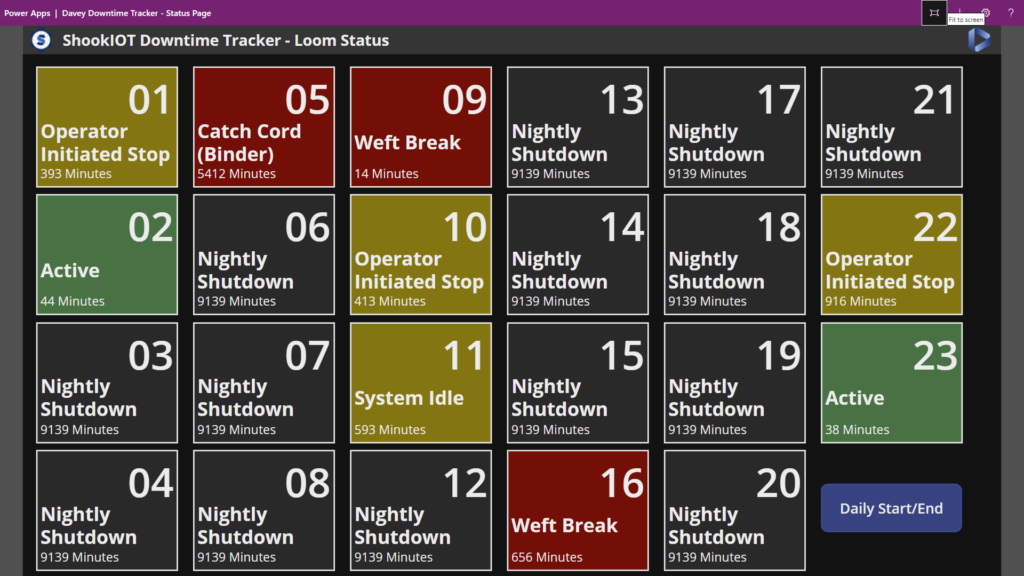

ShookIOT developed an automated, easy to use, Downtime Tracker. Data is automatically collected and displayed in real time for all loom status changes, and production counter values are aggregated and transmitted on 1-minute intervals per loom. Operators are automatically notified when looms experience downtime. Reason codes (such as scheduled maintenance or inventory planning) can be manually inputed. A comprehensive PowerBI report are then created to analyze the downtime data collected and a comprehensive PowerBI report was then created. This data can be used to compare with performance of other looms and product SKUs.

In this project, the ShookIOT Fusion Cloud Historian was successfully deployed and configured to match the data models of the looms. ShookIOT worked with Davey to install custom-manufactured IoT data collection devices for each of the looms. The Downtime and production monitoring data collected were then stored and uploaded into the Microsoft Azure Cloud.

ShookIOT’s components that were implemented include:

- Fusion™: Manages real-time and historical operational data in the cloud – first-native cloud data historian

- Lenses™: Organizes data to make it easier for users to find it

- Essentials™: Provides access in an open format to visualization, analytics, orchestration, and reporting data consumers

- Trackers: Tracks equipment downtime and failure reasons

Benefits

The ShookIOT Downtime Tracker enabled Davey Textile to achieve their goals through:

- Increasing downtime visibility, availability, asset utilization, and efficiencies

- Eliminating bottlenecks and root causes of downtime events

- Predicting and reducing unplanned downtime to maximize output and profit

- Improving and simplifying communication using a single and standardized source for downtime and production reports

- Creating reports for machine performance to highlight the impact of operation improvements

Copyright © ShookIOT 2021. All Rights Reserved.

Davey Textile has been offering textile solutions since 1986 through their manufacturing facility and warehouse located in Edmonton, Alberta, Canada as well as a distribution warehouse in Houston, Texas, USA. They serve local markets and continue to expand globally.

Davey have looms producing all of their textile solutions including fabrics used for Personal Protective Equipment (PPE).

Davey’s philosophy is to create premier products and always committed to quality and service with their motto “don’t just be seen, be safe”.