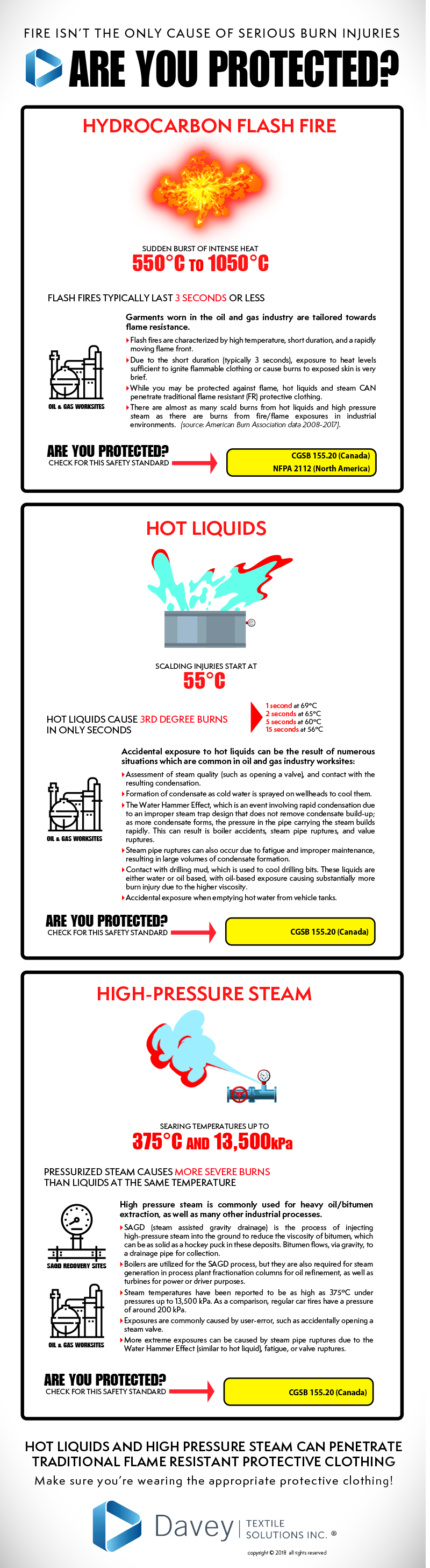

Hydro Carbon Flash Fire – Sudden burst of intense heat. 550 degrees to 1,050 degrees Celsius

Flash fire typically last 3 seconds or less

Garments worn in the oil and gas industry are tailored towards flame resistance.

Flash fires are characterized by high temperature, short duration, and a rapidly moving flame front.

Due to the short duration (typically 3 seconds), exposure to heat levels sufficient to ignite flammable clothing or cause burns to exposed skin is very brief.

While you may be protected against flame, hot liquids and steam CAN penetrate traditional flame resistant (FR) protective clothing.

There are almost as many scald burns from hot liquids and high pressure steam as there are burns from fire/flame exposures in industrial environments. (source: American Burn Association data 2008-2017).

Check the Safety Standard. CGSB 155.20 (Canada). NFPA 2112 (North America)

Hot Liquids – Scalding injuries start at 55 degrees celsius. Hot liquids cause 3rd degree burns in only seconds.

Accidental exposure to hot liquids can be the result of numerous situations which are common in oil and gas industry worksites:

Assessment of steam quality (such as opening a valve), and contact with the resulting condensation.

Formation of condensate as cold water is sprayed on wellheads to cool them.

The Water Hammer Effect, which is an event involving rapid condensation due to an improper steam trap design that does not remove condensate build-up; as more condensate forms, the pressure in the pipe carrying the steam builds rapidly. This can result is boiler accidents, steam pipe ruptures, and value ruptures.

Steam pipe ruptures can also occur due to fatigue and improper maintenance, resulting in large volumes of condensate formation.

Contact with drilling mud, which is used to cool drilling bits. These liquids are either water or oil based, with oil-based exposure causing substantially more burn injury due to the higher viscosity.

Accidental exposure when emptying hot water from vehicle tanks.

Check the Safety Standard. CGSB 155.20 (Canada)

High Pressure Steam – Searing temperatures up to 375 degrees celsius. Pressurized steam causes more sever burns than liquids at the same temperature.

High pressure steam is commonly used for heavy oil/bitumen extraction, as well as many other industrial processes.

SAGD (steam assisted gravity drainage) is the process of injecting high-pressure steam into the ground to reduce the viscosity of bitumen, which can be as solid as a hockey puck in these deposits. Bitumen flows, via gravity, to a drainage pipe for collection.

Boilers are utilized for the SAGD process, but they are also required for steam generation in process plant fractionation columns for oil refinement, as well as turbines for power or driver purposes.

Steam temperatures have been reported to be as high as 375oC under pressures up to 13,500 kPa. As a comparison, regular car tires have a pressure of around 200 kPa.

Exposures are commonly caused by user-error, such as accidentally opening a steam valve.

More extreme exposures can be caused by steam pipe ruptures due to the Water Hammer Effect (similar to hot liquid), fatigue, or valve ruptures.

Check the Safety Standard. CGSB 155.20 (Canada)

HOT LIQUIDS AND HIGH PRESSURE STEAM CAN PENETRATE TRADITIONAL FLAME RESISTANT PROTECTIVE CLOTHING

Make sure you’re wearing the appropriate protective clothing!